Durham isn’t just getting another pizza shop. With Timber Pizza Co. opening its second Triangle location at 501 Washington St., the city is plugging directly into one of the most influential modern pizza stories in America — a wood-fired brand that went from a ’67 Chevy truck to Michelin Bib Gourmand status and national expansion.

For pizza enthusiasts, shop owners, and suppliers, Timber’s arrival is basically a masterclass in where pizza is going next: high-heat ovens, long-fermented dough, playful toppings, and obsessive attention to guest experience.

This piece breaks down how you can steal Timber’s playbook — whether you’re dialing in your best home pizza oven setup, rethinking your pizza shop marketing strategies, or figuring out smarter bulk pizza ingredients and commercial pizza equipment choices.

From Truck to Bib Gourmand: Why Timber Pizza Co. Matters

Timber was born in Washington, D.C., when founders Chris Brady and Andrew Dana walked away from corporate sales and into a wood-fired oven. As Dana told Washingtonian:

“We both hated our jobs—just hated them—but liked lunch… We thought, ‘It’s not rocket science. We can figure this out.’”

— Andrew Dana, co-founder, Timber Pizza Co. source

They towed a mobile oven behind a blue ’67 Chevy, baked at farmers markets and breweries, and eventually opened brick-and-mortar in Petworth. From there, things escalated fast: Bib Gourmand honors, expansion across the Mid-Atlantic, and now multiple Carolina locations including Durham’s Wye Junction development.

CEO Luke Watson has been clear about what sets Timber apart:

“The crust is absolutely amazing. It’s the No. 1 thing people comment on when they try our pizza.”

— Luke Watson, CEO, Timber Pizza Co. source

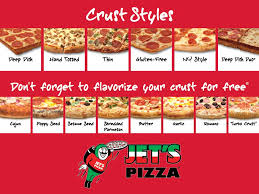

That “Neapolitan-ish” crust — light and airy like Naples, but with New York crunch — is backed by 48-hour dough fermentation, wood-fired heat, and a menu that doesn’t care about rigid tradition. As Dana put it:

“We didn’t want to do classic Neapolitan dough. We wanted it crispier.”

— Andrew Dana source

Durham’s new shop follows the same formula the News & Observer highlighted: red, green, and white pies, creative vegetarian builds like The Lucy and The Green Monster, and meat-forward hits like The Bentley — all in a compact, community-driven dining room with reclaimed wood and mural art.

What Home Pizza Nerds Can Steal from Timber (Even Without a Wood-Fired Oven)

You don’t need a Michelin inspector in your kitchen to bake smarter. Here’s how Timber’s playbook translates directly to your home setup.

1. Turn Heat into Your Superpower

Timber’s entire identity sits on top of a screaming-hot oven. At home, that means investing in the best home pizza oven you can justify — something that reliably hits 800–900°F — or at minimum pairing your standard oven with a heavy pizza stone or steel.

Add a few must-have pizza making tools:

- A thin metal peel for launching

- A turning peel for rotating in a small oven

- An infrared thermometer to know when your stone is actually ready

These basics alone will move you miles closer to that blistered Timber-style crust.

2. Treat Dough Like a Two-Day Project, Not a One-Hour Task

Timber’s dough ferments for roughly two days, which builds flavor and structure. You can mimic this with a solid pizza dough recipe and a 24–48 hour cold ferment in your fridge.

Start with:

- High-protein flour (12–13%)

- Hydration in the 62–68% range

- A digital scale (no cups, ever)

If you want done-for-you, step-by-step formulas tuned for home ovens, dive into the recipes on Pizzaiolo — from classic Neapolitan to New Haven-style char.

3. Upgrade Your Ingredients the Way Timber Does

Timber’s menu leans heavily on local produce, smart cheese blends, and layered textures — everything from roasted sweet potatoes and kale to spicy honey, chorizo, soppressata, and micro cilantro.

For home cooks, that means:

- Swap commodity mozzarella for artisanal pizza ingredients — better cheese, better olive oil, better tomatoes.

- Use Pesto + greens (like the Green Monster) to get more color and flavor with fewer toppings.

- Build pies around seasonal vegetables: squash in fall, zucchini in summer, bitter greens in winter.

Curated ingredient combos and sauce variations are laid out clearly on Pizzaiolo, which makes it easier to experiment without reinventing the wheel every time you stretch a dough.

If you need gear and pantry upgrades in one shot, bundles of pizza cookbooks, stones, and tools on Amazon can accelerate your learning curve.

Lessons Timber Offers Pizza Shop Owners

Timber isn’t just a feel-good story; it’s a very modern blueprint for how to build a profitable, scalable pizza concept today.

1. Sell an Experience, Not Just a Slice

Watson is blunt about the brand’s mission:

“Our mission is to serve amazing experiences to our guests. It’s not to serve amazing pizza.”

— Luke Watson source

He describes Timber’s dining rooms as “nineties summer-camp vibes” — reclaimed wood, throwback music, and a big, warm welcome at the door. That’s a marketing funnel disguised as atmosphere.

If you’re rethinking your pizza shop marketing strategies, consider:

- Story-first branding on your walls, menus, and social

- A focused menu with a few unforgettable signatures (think The Bentley-level “house pies”)

- A tight, photogenic interior that makes every Instagram shot free advertising

Deep-dive examples of this kind of storytelling are all over The Pizza Weekly, especially in our coverage of legendary shops and modern expansion plays.

2. Operational Discipline + Smart Tech

Timber makes almost everything in-house — dough, sauces, even ice cream cones — which is labor intensive but controllable. To keep margins healthy, you need tight ops and modern tools:

- A unified pizza POS system that handles online orders, table, bar, and takeout in one flow

- Integrated pizza delivery software for live tracking, automatic text updates, and geo-targeted promos

- Customer loyalty pizza programs that reward repeat guests with exclusive pies or early access to specials

If you’re upgrading hardware and software, shortlisting options via curated restaurant tech and POS systems can save you time (and a lot of painful switching later).

3. Community-First Beats Ad-First

Watson has said his team leans away from heavy paid marketing and toward partnerships and local causes — sponsoring youth sports, supporting local charities, and embedding in neighborhoods.

That sort of grassroots playbook is exactly the kind of approach we unpack in depth in features like Who Really Stuffed The Crust First?, where independent operators out-innovate big chains with creative ideas and local storytelling.

What Suppliers and Equipment Partners Should Be Watching

Durham’s Timber shop — like the new Raleigh and Charleston locations — is a quiet case study in how high-performing pizza brands buy and use product.

Key angles for suppliers:

- Bulk pizza ingredients: Long-fermented dough and consistent cheese blends demand reliable flour, dairy, and tomato supply at scale.

- Commercial pizza equipment: Wood-fired ovens, specialized mixers, dough presses, and refrigerated prep lines are all part of the ecosystem. Upgrading your portfolio of commercial mixers, dough presses, and other core hardware puts you right where fast-growing pizza brands live.

- Food service technology pizza: From production planning to waste tracking, tech that helps shops trim labor and food costs is now essential, not optional.

- Sustainable pizza sourcing: Timber’s emphasis on fresh, local ingredients mirrors a broader tilt toward traceable flour, better tomatoes, and eco-conscious packaging. Aligning with sustainable pizza sourcing isn’t just PR — it’s increasingly a sales requirement.

If you’re looking for operators actively buying at scale, our pizza suppliers directory is a strong starting point for finding—and becoming—trusted partners in this space.

FAQ: Timber Pizza Co., Home Pizza, and the Future of the Slice

Q1. What can home cooks learn from Timber Pizza Co.’s crust?

Timber’s “Neapolitan-ish” crust is built on high heat plus long fermentation. For home cooks, that means using the best home pizza oven or a blazing-hot stone, and following a 24–48 hour pizza dough recipe cold ferment for deeper flavor and better structure.

Q2. I’m opening a small shop. Where should I spend first: oven or tech?

Your oven is non-negotiable — it defines your style. Get the right heat and throughput, then quickly layer in a capable pizza POS system and pizza delivery software so you’re not drowning in tickets and third-party tablets. Starter options and hardware bundles for pizza ovens and restaurant POS gear are a smart way to phase investment.

Q3. Where can I find reliable bulk pizza ingredients and suppliers?

Look for partners who understand fermentation, high-protein flour, and cheese consistency — not just lowest bid. Our pizza suppliers directory is curated specifically for operators who care about quality, scale, and long-term relationships.

Q4. How does sustainable pizza sourcing actually show up on the plate?

In practice, sustainable pizza sourcing looks like: regionally milled flours, tomatoes with traceable origin, responsibly produced cheese, and packaging that doesn’t trash your local waste system. Shops that align their bulk pizza ingredients with these standards often see stronger customer loyalty and better brand story.

Q5. Where can I dive deeper into pizza history facts to inspire my menu?

If Timber represents “what’s next,” classics like New Haven, Naples, and New York tell you how we got here. Start with our deep dive on Frank Pepe’s coal-fired legacy and century-long impact in A Century of Apizza: Frank Pepe Pizzeria Napoletana for rich, practical pizza history facts you can turn into specials, menu copy, or in-store storytelling.

Final Slice

Timber Pizza Co.’s new Durham shop isn’t just another dot on the map — it’s a signal. High-heat ovens at home, long-fermented dough, bolder toppings, tighter dining rooms, smarter tech, better sourcing: this is where pizza is heading, from backyard setups to multi-unit brands.

Whether you’re experimenting with your next pizza dough recipe in a tiny apartment kitchen, shopping for a serious pizza oven and stone, negotiating with mills for bulk pizza ingredients, or rethinking your pizza shop marketing strategies, there’s something very real to learn from the way Timber builds crust, community, and growth — one pie at a time.

This article contains affiliate links, which means Pizza Magazine may earn a commission if you make a purchase through them, at no extra cost to you. We only recommend products and services we genuinely believe in